对于

济南通风管道加工的过程中难免会有问题的发生,下面讲解两个发生比较普遍的问题,从管道倾斜角度和弯头角度以及管道加工材料方面来看看看吧。

For Jinan ventilation pipe processing, there will inevitably be problems. Here are two common problems, which can be seen from the angle of pipe inclination, elbow angle and pipe processing materials.

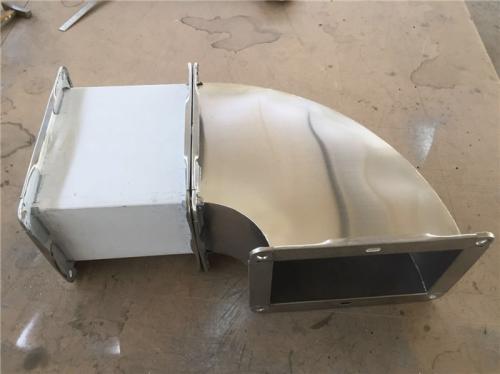

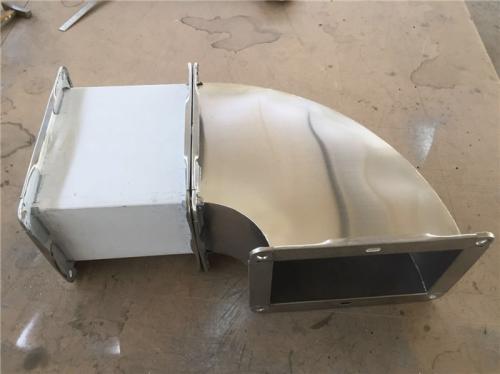

1、管道倾斜角度和弯头角度不正确

1. Incorrect pipe inclination and elbow angle

性能:折叠角不平直;矩形风管的两个相对平面与两端不平行;咬人不严格;对角线不相等。

Performance: the folding angle is not straight; The two opposite planes of rectangular duct are not parallel to both ends; The bite is not strict; Diagonal lines are not equal.

原因:管道成对平行,相对板的长度和宽度不相等;板材下料放样设置的不正确。

Cause: The pipes are parallel in pairs, and the length and width of the opposite plate are not equal; The setting of sheet blanking and lofting is incorrect.

影响:会在通风管道上造成不均匀的力,安装的管道不平直,法兰垫圈不牢固,并且系统泄漏,从而导致空调负荷损失,导致使用寿命缩短。

Impact: It will cause uneven force on the ventilation pipe, the installed pipe is not straight, the flange gasket is not firm, and the system leaks, resulting in the loss of air conditioning load and the shortening of service life.

措施:展开和下料时,应严格限制板材的直角,将板材的长度,宽度和检查对角线控制在允许范围内;落料后,管道相对部分的两块板应重叠以检查尺寸精度。

Measures: During unfolding and blanking, the right angle of the plate shall be strictly limited, and the length, width and inspection diagonal of the plate shall be controlled within the allowable range; After blanking, the two plates in the opposite part of the pipe shall be overlapped to check the dimensional accuracy.

2、管道加工材料不符合标准

2. The pipe processing material does not meet the standard

性能:管道表面下沉,侧面向外突出,变形明显;板的表面不平整,厚度不均匀,有明显的压痕,裂纹,砂眼,疤痕和生锈。

Performance: the pipe surface sinks, the side protrudes outward, and the deformation is obvious; The surface of the plate is uneven, with uneven thickness, obvious indentation, crack, sand hole, scar and rust.

原因:该材料不合格,不能满足制造风管的要求。

Cause: The material is unqualified and cannot meet the requirements for manufacturing air duct.

影响:操作期间风管泄漏,空调负荷增加以及风管寿命和性能受到影响。

Impact: air duct leakage, air conditioning load increase, and air duct life and performance are affected during operation.

措施:在制造管道之前,有必要检查材料出厂合格证书,材料合格证书,外观厚度等,以确保材料可用。

Measures: Before manufacturing pipes, it is necessary to check the factory certificate, material certificate, appearance thickness, etc. of materials to ensure the availability of materials.

The above is the explanation of the relevant content of the question "Two common problems in the processing of ventilation ducts". I hope you have a new understanding. Of course, if you are worried about its purchase, installation or use, you can come to our website at any time http://www.jntfgd.com Consult and understand!

上一篇:风管的安装及中间检验从三个方面了解

下一篇:合理的设备布局为排烟罩的选择提供方便